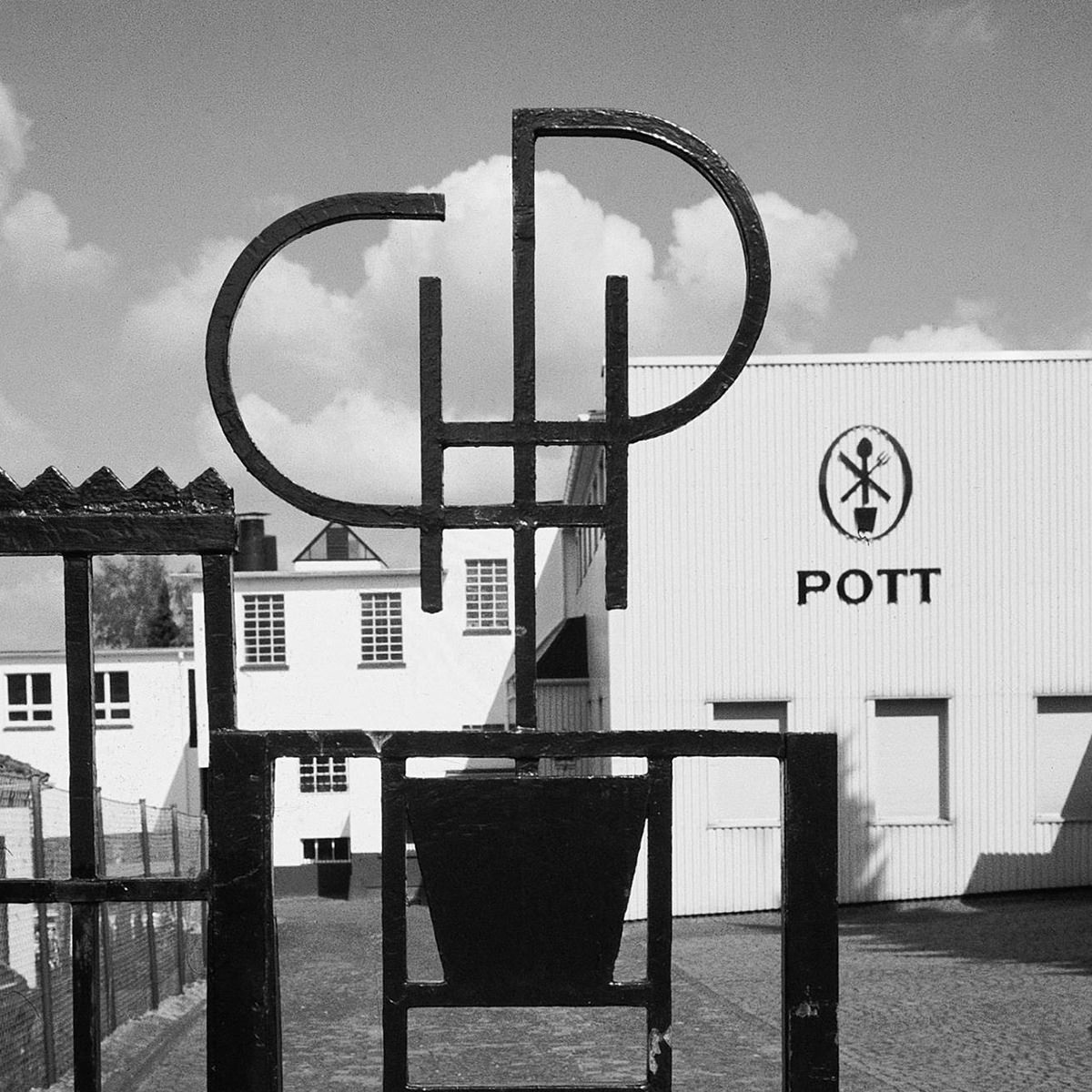

Manufactory

For over 100 years, Pott products were manufactured at the founding site in Solingen. Today, Pott flatware is manufactured at the Mono manufactory in Mettmann (20 km from Solingen). In 2006, the company Pott passed into the ownership of the Seibel family, which has a successful and equally more than a hundred-year tradition in the handcrafted production of cutlery.

1/

4

Compared to their modern, elegant appearance, the production of Pott flatware seems almost archaic. Before you hold one of them in your hands, it has passed through the experienced hands of master craftsmen at the manufactory in Mettmann, who work on each piece with infinite patience and care until it meets the highest quality standards.

The traditional craftsmanship techniques have been refined over the decades. Deburring, smoothing, sharpening, sanding, polishing, brushing, grinding, in between always pausing and checking - every detail, every nuance receives the full attention of the craftsmen.

With a trained eye and "music in their hands", they perform precision work reminiscent of Swiss watch making and the cutting of diamonds, which cannot be replaced by any computer-controlled machine.

A spoon and a fork require more than 30 working steps each, and a knife requires more than 90. The result of this immense effort is the quality and durability of each Pott flatware.

The Pott table knives are forged by hand in a Solingen manufactory using traditional manufacturing methods. Made of molybdenum-vanadium steel, the knife blades are made to glow at 1050° and formed under the forge hammer with two tons of pressure.

After cutting out the basic shape, the blade is heated again to 1050°. By slowly cooling it down to 80°, the blade is now hard on the inside and elastic on the outside.

Another crucial step in the total of 90 work steps is "blue polishing," an elaborate grinding method in which the surface of the blade is extremely compacted and finely sealed. This increases its resistance to rust.

The insertion, "Reiden", of the blade into the hollow handle with quartz sand filling enables the balanced weight of each table knife. The Pott-specific micro-serration, a serration barely visible to the naked eye, guarantees extreme sharpness.

Learn more about...